Challenging and innovative

TC-800Q full-automatic window pasting machine is the special equipment for pasting window colour boxes and colour boxes.

This automatic window patching machine is suitable for pasting all window products such as mobile phone boxes, wine boxes, napkin boxes, etc. What's more, it is one of the most advanced window pasting machines in China at present. The perfect humanized design concept makes this automatic window patching machine have the characteristics of high efficiency, high precision, high stability and simple operation.

This automatic window patching machine is suitable for paper jam and corrugated paper. The paper pile is separated by a single sheet in the way of bottom drawing without stopping the machine to feed paper.

After pushing the specified position, printing glue on the flexible plate module and cutting and cutting the stable and accurate diaphragm, the film pasting function is realized on the windows of a tissue box, gift box, toy box shirt box, milk box, etc.

Mechanical distribution of paper, positioning, glueing, sticking film, paper are five major parts.

This automatic window patching machine has a reasonable design, stable quality and is simple operated and easy to learn. It is a sharp weapon in the printing and packaging industry.

TC-800Q full-automatic window pasting machine is the special equipment for pasting window colour boxes and colour boxes.

This automatic window patching machine is suitable for pasting all window products such as mobile phone boxes, wine boxes, napkin boxes, etc. What's more, it is one of the most advanced window pasting machines in China at present. The perfect humanized design concept makes this automatic window patching machine have the characteristics of high efficiency, high precision, high stability and simple operation.

This automatic window patching machine is suitable for paper jam and corrugated paper. The paper pile is separated by a single sheet in the way of bottom drawing without stopping the machine to feed paper.

After pushing the specified position, printing glue on the flexible plate module and cutting and cutting the stable and accurate diaphragm, the film pasting function is realized on the windows of a tissue box, gift box, toy box shirt box, milk box, etc.

Mechanical distribution of paper, positioning, glueing, sticking film, paper are five major parts.

This automatic window patching machine has a reasonable design, stable quality and is simple operated and easy to learn. It is a sharp weapon in the printing and packaging industry.

Second, electrical equipment

Frequency conversion speed regulators for electrical components, programmable controllers, i.e. PLC computers, photoelectric switches, etc. are all set up

Da Huichuan and other world-famous brands. General switches, contactors and relays are all made by Schneider, France.

The design is stable and does not cut corners. The main wallboard of the whole machine is made of 30mm thick steel and processed by the processing centre.

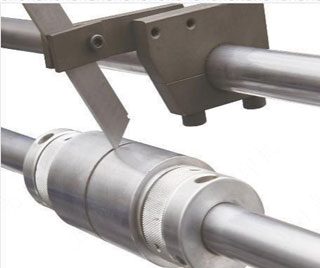

Only the glueing roller and pasting roller of the machine can be processed by a high-precision numerical control lathe at one time. All ex-factory parts have been inspected to ensure they are qualified. If there is any discrepancy, our company shall bear legal responsibility.

The paper feeding department adopts the brand of ever-power imported from the United States and cooperates with our company's unique pallet intermittent paper feeding method to ensure smooth and stable paper feeding and prevent double sheets and empty sheets. The air suction belt and paper delivery belt use an imported Sieglin leather belt, which is durable.

Third, assembly standards

The assembly requirements of all models of our company are relatively high, so our company has formulated many higher standard parts tolerances

For assembly level, if the tolerance of axle position is set within 0.02mm, the hardness of quenched parts should be greater than 40, and the best process-hot assembly should be used for bearing assembly, so as to prevent dead beating and hard beating. Clear tolerance records should be kept for the assembled parts, and the empty car operation should be ensured for 48 hours. The axle position temperature should not be higher than the indoor temperature by 15 degrees, and 1,000 sheets of 350 grams of paper should be used for travelling.

Never stop the car when driving, and resolutely eliminate the noise that the whole machine should not have. Every machine is recorded at the time of acceptance. If it exceeds the accepted standard, it will be regarded as unqualified and cannot leave the factory.

Model | Model | TC-1100A |

Maximum paper delivery | Max.PaperSize | 1100×650mm |

Minimum paper feed | Min.PaperSize | 100×100mm |

Maximum patch size | Max.filmSize | 850×500mm |

Minimum patch size | Min.filmSize | 40×20mm |

Diaphragm thickness | Film Sheet Thickness | 0.03-0.3mm |

Maximum machine speed | Max. working speed | 10000s/h |

Adapt to paper jam | Cardboard | 250-1200g/m² |

Adapt to corrugated paper | Corrugated Paper | ≤5mm |

total power | Total Power | 8Kw |

Overall weight | Total weight | 2980kg |

external dimensions | Overall Dimensions | 4800×1800×1520mm |

external dimensions (when rubber roller is pulled out) | Overall Dimensions (Whentherollerispulledout) | 4800×2650×1520mm |

Serial number | Category name | Specification brand | Origin and Remarks |

1 | Frequency converter | 2.2KW | Delta, Huichuan (optional) |

2 | Programmable Logic Controller (PLC) | H2u-48 | Delta, Huichuan (optional) |

3 | Man-machine interface (touch screen) | B-07 | Delta, Huichuan (optional) |

4 | Photoelectric switch (electric eye) | D61 | Omron |

5 | Relay | Schneid er | |

6 | Feed servo motor | 1.5KW | De lta Huich uan ( Optio nal) |

7 | Film feed servo motor | 750W | Delta Huichuan (Optional) |

8 | Button | Schneid er | |

9 | Contactor | Schneid er | |

10 | Key bearing | SKF | Sweden |

11 | Other bearings | HER | Harbin |

12 | Paper feeding belt | Taiwan | |

13 | Air suction belt | Taiwan | |

14 | Paper collecting belt | Taiwan | |

15 | Joint bearing | SF | South Korea |

16 | linear LM12UU | HHY | South Korea |

17 | Linear guide EGH25CA | HIWIN | Taiwan |

18 | Proximity switch | AUTONICS | South Korea |

19 | Ac contactor | Schneider | France |

20 | Thermal relay (thermal overload protector) | Schneider | France |

21 | Air switch | LS | South Korea |

22 | Button | Schneider | France |

23 | Gear motor | WANSHSIN | Taiwan |

24 | Main motor | DEDONG | China |

25 | Air circuit system | SNS | China |

This machine uses a 7 inch touch display screen and a host computer

(PLC) to digitally adjust the film length, counting, etc.

The paper feeding part is driven by a 1.5kW servo motor to ensure the high-speed stability of paper feeding.

The most common push-and-hold position in the world is adopted to ensure the fitting precision.

Rotary hobs are adopted to accurately divide the whole roll of diaphragm according to the required length.

Install the whole roll of membrane on the membrane rack and adjust the left and right positions.

Cam structure is adopted to intermittently cut the box (such as tissue box, etc.)

whose diaphragm needs to be opened.

The left and right positions of the diaphragm are adjusted without stopping by rotating the hand knob.

Through the rotation of the hand knob, the left and right glue positions can be adjusted without stopping.

Through harmonic differential, adjust the positions before and after gluing without stopping.

The front and rear positions of the diaphragm are adjusted without stopping through the harmonic differential.

The paper conveying belt adopts 8-10 endless paper conveying belts made of natural rubber to improve the paper conveying stability.

The encoder and photoelectric switch are adopted to adjust the accurate paper feeding time

A 1.5KW servo motor of a well-known brand is adopted to ensure the high-speed stability of paper feeding.

750W well-known brand servo motor and high-precision reducer are used to realize precise film feeding and ensure the film length accuracy within

0.1 mm.

Through the rotation of the hand knob, the glue quantity can be adjusted without stopping.

The left and right position adjustment of the push gauge chain is realized through a screw rod rotation mode.