Challenging and innovative

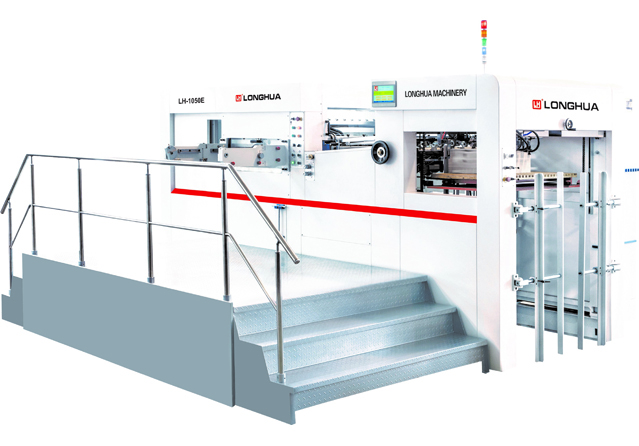

We designed 1050E Automatic Die Cutting Machine, which is the greatest research and development and manufacturing of new equipment with a higher degree of intelligence.

This machine adopts numerous advanced pneumatic and servo driving processing technology from abroad. After the strict assembly quality control, it has advantage of simple operation and safe reliable.

It could creasing and die cutting after printing products, such as more than 80g/m2 paper, cardboard, corrugated paper below 4mm, pasting paper, laminating paper and so on.

Good quality and design makes machine work stably and safety when machine’s speed reach 7500 sheets/h. This machine will provide you to enjoy the comfortable operation and faster return on investment.

We designed 1050E Automatic Die Cutting Machine, which is the greatest research and development and manufacturing of new equipment with a higher degree of intelligence.

This machine adopts numerous advanced pneumatic and servo driving processing technology from abroad. After the strict assembly quality control, it has advantage of simple operation and safe reliable.

It could creasing and die cutting after printing products, such as more than 80g/m2 paper, cardboard, corrugated paper below 4mm, pasting paper, laminating paper and so on.

Good quality and design makes machine work stably and safety when machine’s speed reach 7500 sheets/h. This machine will provide you to enjoy the comfortable operation and faster return on investment.

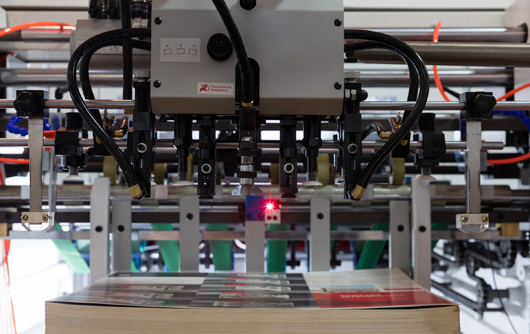

Taiwan imported high precision Feeder

Four suction nozzles, four sending nozzles, ensure feed smoothly.

Suction angle and height is adjustable

Non-stop paper feeding device

Import screw air-blowing device, it could

make the sheet send smoothly.

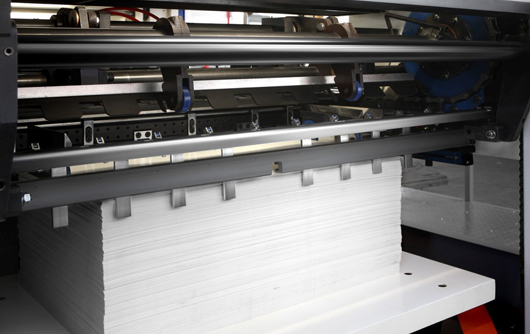

The design of stacker preparatory stage was improved, it could use prepared car sheet piling. Also could use ordinary hydraulic car sheet piling to stacker directly.

The incline-type paper moving table top is more suitable to high-speed thin paper and location. Side location adopt dual purpose side device with pull guide and push guide, accounting to paper choose, it makes switch easier. It could switch front rise position arriving reduction of speed device, it is benefit of thin paper’s location.

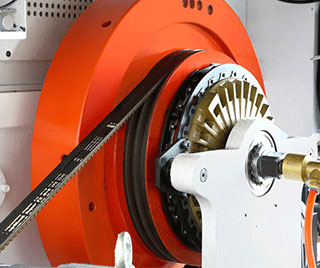

The driving gear ensures high speed of die cutting together. The pneumatic locking mechanism and air clutch are fast and stable. The die cutting frame can prevent the die cutting plate from drooping or separating effectively.

Delivery section adds tester into the security system. It is equipped with an inset counter. Using subsection could adjust brush and sheet air-blowing device, so the finished product of delivery section could product stably. Gripper drive train expanded buffer device. Non-stop paper delivery brings high return!

Machine Parameters:

Max. Paper Size 1050×750 mm |

Min. Paper Size 400×360 mm |

Max. Cutting Size 1040×720 mm |

Inner Chase Size 1080×745 mm |

Steel Plate Size 1080×736 mm |

Processed Materials Cardboard:80~2000 g/m² Corrugated Paper:≤4mm |

Max. Pressure 300 N/cm² |

Gripper Margin 8 mm |

Max. Working Speed 7500 s/h |

Total Power 20 kw |

Total Weight 16.0 T |

Dimension (L×W×H) 6300×4200×2100 mm |

Configuration:

No. | Accessory | Brand | Place of Origin |

1 | Photoelectric Switch | SUNX | Japan |

2 | HMI | WEINVIEW | Taiwan |

3 | Button | SCHNEIDER | France |

4 | A.C. Contactor | SIEMENS | Germany |

5 | PLC | MITSUBISHI | Japan |

6 | Electric Horn | QLIGHT | Korea |

7 | Magnetic Valve | SMC | Japan |

8 | Oil-water Separator | AIRTAC | Taiwan |

9 | Motor Breaker | SIEMENS | Germany |

10 | Main Motor | TECO | Taiwan |

11 | Gear Motor | CPG | Taiwan |

12 | Oil Pressure Switch | ARK | Korea |

13 | Pneumatic Clutch | OMPI | Italy |

14 | Paper Feed Clutch | MIKIPULLEY | Japan |

15 | Torque Limiter | JASU | Taiwan |

16 | Indexing Drives | HANDEX | Taiwan |

17 | Vacuum Pump | BECKER | Germany |

18 | Feeder | YONGCHUAN | Taiwan |

19 | Feeder Nozzle | SILENT | Sweden |

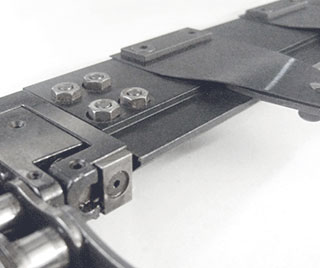

20 | Tooth Row Drive Chain | RENOLD/IWIS | Britain/Germany |

21 | Other Drive Chain | TYC | Taiwan |

22 | Tooth Row | JASU | Taiwan |

23 | Bearing | FALA/IKO | Germany/Japan |

24 | Rotary Joints | DEUBLIN | America |

25 | Timing Belt | MEGADYNE | Italy |

26 | Paper Feed Belt | CODONBELT | Switzerland |

27 | Mould Coil Spring | TOHATSU | Japan |

28 | Worm&Worm Wheel | LIMING | Taiwan |

29 | Oil Temp.Conditioning System | WLP | Taiwan |

30 | Cooling Fan | SUNON | Taiwan |

31 | Pull lay | JASU | Taiwan |

32 | Lubrication Pump | JIGUANG | Taiwan |

33 | Encoder | OMRON | Japan |

34 | Sealing Ring | CTY | Germany |

35 | Frequency Converter | HPMONT | Joint-venture |

36 | Body Material | Ductile Iron QT600-3 |

Note:the accessories of machines can be changed in the process of upgrading, with no less than the existing brand

quality, the seller will reserve the right, no longer separate notification.

The high quality pneumatic clutch reduces noise and minimizes impact when stopping the machine at a high speed.

With a programmable lubrication system, the accurate control of PLC ensures balanced lubrication of the machine.

Adopt imported equipment, improve the stability of the machine, low noise, high performance, long service life.

The grippers are made of special extra hard aluminum alloy, with anode treatment on the surface, ensuring accurate die cutting and embossing, ect. at high speed. The adjustment mechanism, patent design guarantees very accurate control. An imported chain is used for the main gripper transmission, with strength increased by 45% for accurate stability and prolonged life.